Revolutionizing the Industry: How a Premier Road Cleaning Vehicle Manufacturer Integrates Cutting-Edge 3D Printing Technology for Superior Business Success

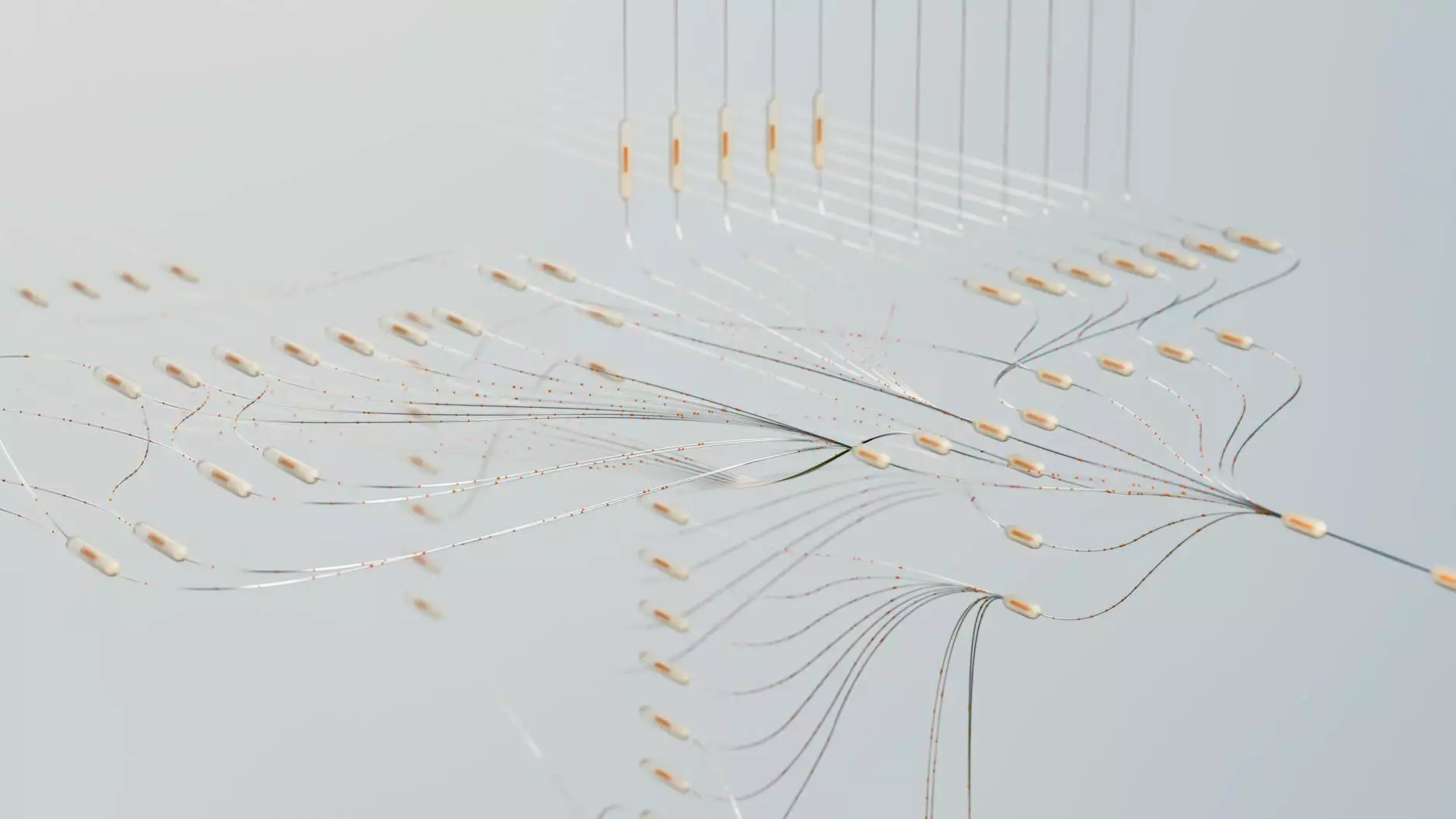

In today’s highly competitive industrial landscape, innovation is not just an advantage; it is a necessity. Companies that continuously evolve by adopting advanced technologies tend to outperform their competitors and set new benchmarks of efficiency, quality, and sustainability. Among these groundbreaking advancements, 3D printing has emerged as a game-changer, especially in high-precision manufacturing disciplines such as the road cleaning vehicle industry.

Understanding the Power of 3D Printing in Modern Business

3D printing, also known as additive manufacturing, is a revolutionary process that creates complex parts layer by layer from digital models. This technology offers several significant benefits:

- Rapid prototyping: Rapidly turn ideas into tangible prototypes, reducing development cycles.

- Cost efficiency: Minimize material waste and reduce tooling costs compared to traditional manufacturing methods.

- Customization: Easily produce bespoke components tailored for specific client needs.

- Complex geometries: Achieve intricate designs that are impossible or costly with conventional manufacturing.

- Sustainable production: Use eco-friendly materials and reduce carbon footprint through efficient processes.

The Role of 3D Printing in Enhancing the Capabilities of a Road Cleaning Vehicle Manufacturer

For a company like ceksansweepers.com, specializing in the manufacturing of road cleaning vehicles, integrating 3D printing technology is instrumental for several operational and strategic reasons:

1. Accelerated Product Development and Innovation

By utilizing 3D printing, manufacturers can quickly prototype new vehicle components, enabling faster iterations and refinement. This agility accelerates the development process, allowing companies to bring innovative solutions to market swiftly. For instance, creating custom parts such as nozzles, brushes, and mounting brackets can be done rapidly, reducing lead time from concept to production.

2. Customization and Client-Centric Solutions

Every city or municipality has unique requirements for road cleaning, necessitating tailored vehicle configurations. 3D printing allows for on-demand customization of components, ensuring that each road cleaning vehicle manufacturer can deliver highly specialized products aligned with customer specifications, leading to increased satisfaction and competitive advantage.

3. Reduction of Manufacturing Costs and Lead Times

Traditional manufacturing processes often involve expensive tooling, molds, and lengthy supply chains. 3D printing sidesteps many of these obstacles by enabling in-house fabrication of parts. This approach reduces costs associated with tooling and inventory while also cutting down production timelines, which enables faster response to market demands and urgent client requests.

4. Innovation in Design Complexity

Many road cleaning vehicle components require intricate geometries or internal channels for water and waste management. Additive manufacturing makes it feasible to produce such complex designs efficiently. For instance, innovative nozzle designs or integrated mounting systems can be manufactured as single, optimized parts, improving overall performance and reliability.

5. Sustainable Manufacturing and Environmental Responsibility

Adopting 3D printing supports environmental goals by minimizing waste and reducing the need for excess inventory. Moreover, eco-friendly materials suitable for additive manufacturing are increasingly available, allowing road cleaning vehicle manufacturers to produce greener, sustainable products without sacrificing durability or functionality.

Integrating 3D Printing into Business Strategy for a Competitive Edge

For a company aspiring to outperform competitors and cement its position as a leader in the industry, embracing 3D printing is crucial. Here are strategic steps to leverage this technology effectively:

- Invest in state-of-the-art 3D printing equipment: High-resolution, large-format 3D printers expand capabilities, allowing for diverse material use and larger component fabrication.

- Develop a skilled in-house design and manufacturing team: Expertise in CAD modeling and additive manufacturing processes ensures maximum utilization of 3D printing benefits.

- Establish robust material sourcing: Access to advanced materials such as thermoplastics, metals, and composites enhances product performance and longevity.

- Implement a rapid prototyping culture: Encourage continuous testing, refinement, and innovation to stay ahead of industry trends.

- Focus on sustainability: Incorporate eco-friendly materials and energy-efficient processes into your manufacturing workflow.

Success Stories: Leading Road Cleaning Vehicle Companies Utilizing 3D Printing

Many industry leaders have already harnessed the power of 3D printing to revolutionize their production lines:

Case Study 1: EcoSweep Technologies

This manufacturer integrated 3D printing for producing custom nozzles and brush assemblies, reducing assembly time by 40% and achieving faster delivery times. Their ability to offer customized solutions led to expanded contracts with municipal governments worldwide.

Case Study 2: CleanTech Vehicles

By adopting advanced additive manufacturing for prototypes and spare parts, CleanTech significantly cut their development cycle, enabling them to launch innovative features ahead of competitors, solidifying their market leadership.

Future Trends in 3D Printing and Road Cleaning Vehicle Manufacturing

The future of 3D printing in the road cleaning vehicle manufacturer domain includes several exciting developments:

- Use of metal additive manufacturing for producing ultra-durable, wear-resistant parts.

- Integration with IoT and smart manufacturing to enable real-time monitoring and adaptive production processes.

- Development of biodegradable and recyclable materials for environmentally friendly components.

- Hybrid manufacturing processes combining traditional and additive methods for optimal performance and cost-efficiency.

Conclusion: Embracing Innovation with a Vision for the Future

In conclusion, the business of manufacturing road cleaning vehicles is poised for transformative growth powered by 3D printing. Companies like ceksansweepers.com exemplify how leveraging this technology not only enhances product quality, customization, and efficiency but also positions the business as an innovative leader in a competitive landscape.

To stay ahead, it is imperative for manufacturers to invest in additive manufacturing, foster a culture of continuous innovation, and align their strategic goals with the evolving technological landscape. By doing so, they will deliver superior solutions that meet modern expectations for sustainability, performance, and reliability—paving the way for ongoing success and growth in the industry.

Embracing 3D printing makes the frontier of road cleaning vehicle manufacturing more accessible, sustainable, and innovative than ever before. The future belongs to those who innovate today for a cleaner, smarter planet tomorrow.