Understanding Hitachi Hydraulic Pumps: The Key to Efficient Operation

Hitachi hydraulic pumps are essential components in the hydraulic systems of various machinery and equipment. Known for their durability and high performance, these pumps are used across numerous industries, including construction, automotive, and manufacturing. In this article, we will explore the features, advantages, types, and applications of Hitachi hydraulic pumps, as well as valuable maintenance tips to ensure their longevity.

The Importance of Hydraulic Pumps in Modern Industry

Hydraulic pumps are crucial for converting mechanical energy into hydraulic energy, allowing machines to execute heavy tasks effortlessly. Here are some key roles they play:

- Power Transmission: Hydraulic pumps transmit power by moving hydraulic fluid through the system, triggering various functions in hydraulic machinery.

- Control: They help maintain control over speed and torque, providing precision in tasks ranging from lifting loads to moving machining tools.

- Efficiency: Hydraulic systems powered by quality pumps can significantly enhance operational efficiency, saving time and reducing waste.

Why Choose Hitachi Hydraulic Pumps?

With a reputation built over decades, Hitachi hydraulic pumps are synonymous with quality and reliability. Here are several reasons why choosing Hitachi hydraulic pumps can benefit your business:

1. Superior Engineering and Design

Hitachi invests heavily in research and development to create hydraulic pumps that are robust and capable of withstanding harsh operational conditions. Their pumps are designed to be:

- Durable: Built with high-quality materials that resist wear and tear.

- Efficient: Engineered to deliver maximum flow rates while minimizing energy consumption.

- Versatile: Suitable for various applications, from industrial machinery to automotive hydraulic systems.

2. Innovative Technology

Hitachi is at the forefront of hydraulic technology. Their pumps incorporate innovative features such as:

- Smart Controls: Advanced control mechanisms that optimize performance and adjust flow rates based on demand.

- Noise Reduction Technology: Designed to operate quietly, minimizing disruption in work environments.

- Compact Size: Many Hitachi hydraulic pumps are designed to fit into tight spaces while maintaining high performance.

3. Extensive Range of Products

Hitachi offers a wide variety of hydraulic pumps to meet diverse industrial needs. Their product range includes:

- Piston Pumps: Suitable for high-pressure applications where high efficiency is essential.

- Gear Pumps: Known for their simplicity and reliability, ideal for low to medium pressure tasks.

- Screw Pumps: Excellent for transporting viscous fluids with minimal pulsation.

Applications of Hitachi Hydraulic Pumps

Hitachi hydraulic pumps find their application in numerous sectors, proving their versatility and efficiency. Here are some industries where they are extensively used:

1. Construction

In construction, hydraulic pumps are vital for operating machinery such as excavators, bulldozers, and cranes. They ensure the smooth operation of:

- Lifting Equipment: Hydraulic lifts powered by Hitachi pumps lift heavy objects with precision.

- Excavation Machinery: Facilitating digging and trenching work with hydraulic backhoes.

- Concrete Machinery: Ensuring the efficient mixing and placing of concrete.

2. Automotive

In the automotive industry, Hitachi hydraulic pumps are used in various applications, including:

- Power Steering Systems: Providing ease of maneuverability in vehicles.

- Transmission Systems: Assisting in gear changes and overall vehicle functionality.

- Brake Systems: Ensuring the reliable operation of hydraulic brake mechanisms.

3. Manufacturing

Manufacturing processes benefit from Hitachi hydraulic pumps in several ways, particularly in:

- Metal Forming: Used in hydraulic presses for shaping and forming metals.

- Assembly Lines: Powering automated systems for assembly and production lines.

- Material Handling: Facilitating the movement of goods within manufacturing facilities.

Maintenance Tips for Hitachi Hydraulic Pumps

Regular maintenance of hydraulic pumps is essential to ensure longevity and optimal performance. Here are some important maintenance tips for Hitachi hydraulic pumps:

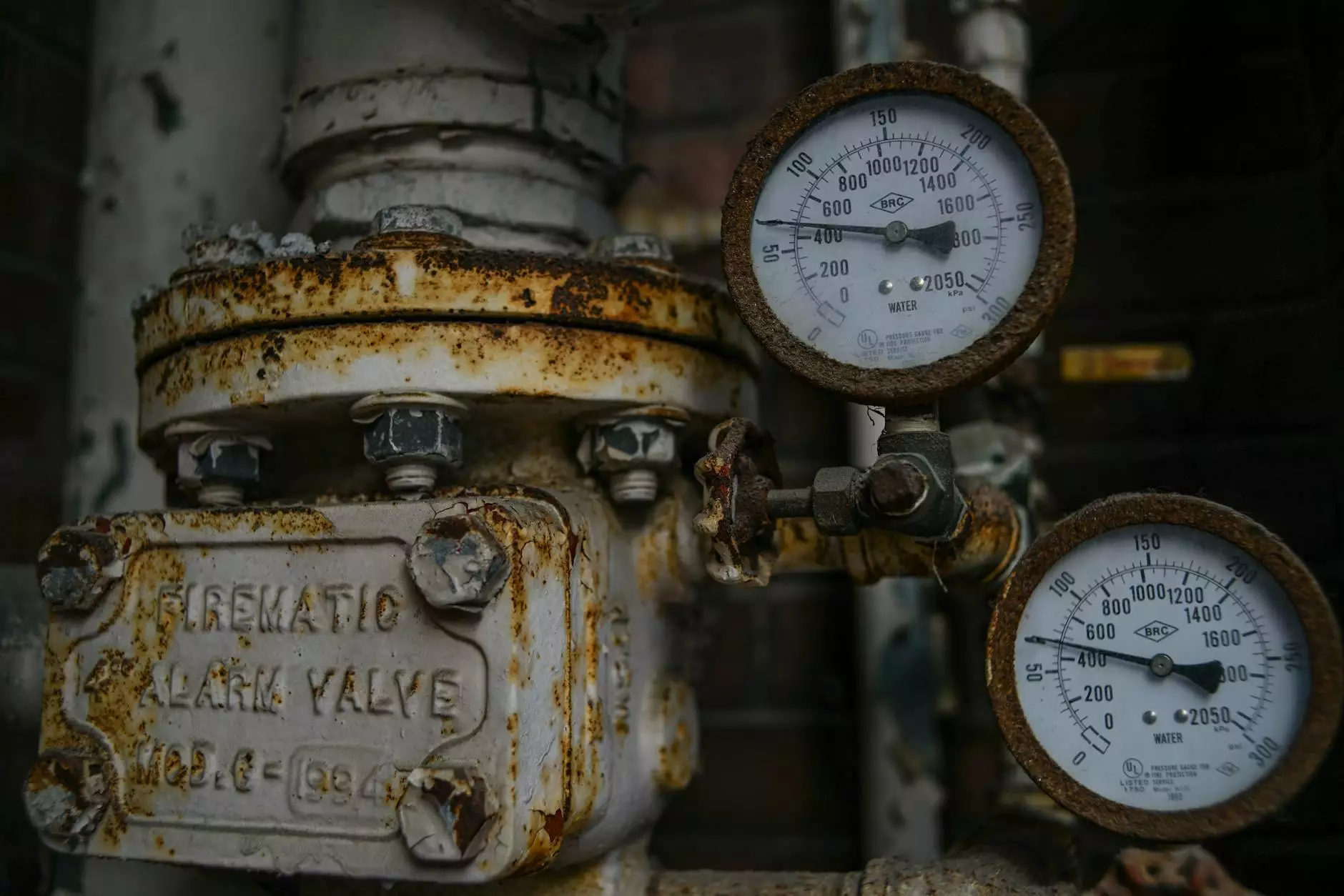

1. Regular Inspection

Conduct frequent inspections to check for:

- Signs of wear or damage to seals and hoses.

- Fluid leaks, which can indicate issues with seals or connections.

- Vibration analysis to identify any irregularities in the pump’s operation.

2. Fluid Quality and Level

Maintaining hydraulic fluid quality is crucial. Ensure that:

- The hydraulic fluid is clean and free from contaminants.

- Fluid levels are checked regularly and topped up as necessary.

- The appropriate type of hydraulic fluid is used, as specified by Hitachi.

3. Replace Filters

Hydraulic filters should be replaced at regular intervals to ensure:

- Preventing contamination of the hydraulic system.

- Maintaining efficient flow and pump operation.

- Extending the life of the hydraulic pump.

Conclusion

Hitachi hydraulic pumps are indispensable in powering various machinery within diverse industries. Their durability, efficiency, and innovative technology make them a preferred choice for many businesses. Investing in high-quality Hitachi hydraulic pumps not only enhances operational efficiency but also reduces long-term costs associated with repairs and replacements.

For reliable Hitachi hydraulic pumps and exceptional customer service, visit Shop Hydraulic America. Our comprehensive selection of auto parts and supplies ensures that your hydraulic needs are met with the highest standards of quality and reliability.