The Expert Guide to CNC Turning Parts Factory Business

Introduction:

Welcome to the world of precision engineering and top-notch quality production! Deepmould, a renowned name in the Metal Fabricators industry, excels in the art of CNC turning parts factory. In this comprehensive guide, we will delve deeper into the realm of CNC turning parts factory business, exploring the intricacies, benefits, and growth opportunities in this thriving sector.

Understanding CNC Turning Parts Factory:

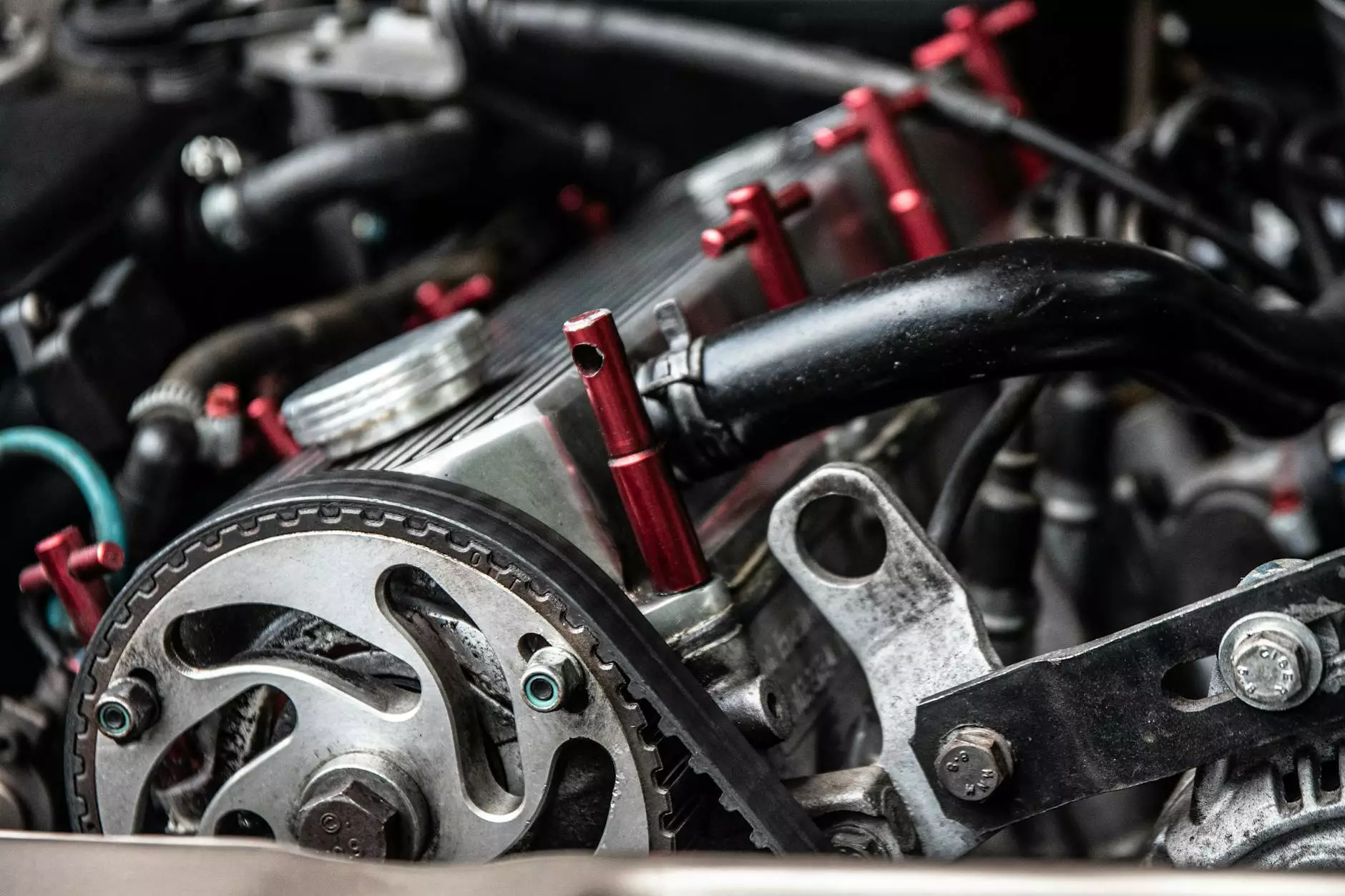

CNC turning parts factory is a specialized manufacturing process that involves the use of Computer Numerical Control (CNC) machines to create precision components through the turning of raw materials. This process allows for high levels of accuracy and repeatability, making it ideal for producing intricate parts with tight tolerances.

The Advantages of CNC Turning Parts Factory:

There are numerous advantages to utilizing CNC turning parts factory for your business needs. Some of the key benefits include:

- Precision: CNC machines offer unparalleled levels of precision, ensuring that each component meets the exact specifications.

- Efficiency: The automated nature of CNC turning reduces production time and minimizes errors, leading to increased efficiency.

- Consistency: With CNC machines, you can expect consistent quality in every part produced, maintaining a high standard across all batches.

- Flexibility: CNC turning allows for the production of complex geometries and shapes, offering versatility in design and manufacturing.

The Process of CNC Turning Parts Factory:

The process of CNC turning parts factory involves several key steps, including:

- Design: Engineers create a detailed CAD model of the part to be manufactured.

- Programming: The CAD model is translated into a CNC program that guides the machine in cutting the material.

- Machining: The CNC machine turns the raw material, removing excess material to form the final component.

- Finishing: The part undergoes finishing processes, such as deburring and surface treatment, to meet quality standards.

Why Choose Deepmould for CNC Turning Parts Factory:

Deepmould stands out as a leader in the CNC turning parts factory business for several reasons:

- Expertise: With years of experience in precision engineering, we have the expertise to handle complex projects with ease.

- State-of-the-Art Facilities: Our advanced CNC machines and modern facilities ensure top-notch quality and efficiency in production.

- Custom Solutions: We offer bespoke solutions tailored to your specific requirements, ensuring optimal results for your business.

- Quality Assurance: Deepmould is committed to maintaining the highest standards of quality, adhering to strict inspection processes at every stage of production.

The Future of CNC Turning Parts Factory Business:

The CNC turning parts factory business is poised for remarkable growth in the coming years, driven by advancements in technology and increasing demand for precision components across industries. As businesses strive for greater efficiency and quality in their products, CNC turning will play a crucial role in meeting these requirements.

Conclusion:

Embark on a journey of excellence with Deepmould, your trusted partner in CNC turning parts factory. Explore the endless possibilities of precision engineering and superior quality production with our state-of-the-art facilities and skilled team. Take your business to new heights with CNC turning parts factory solutions tailored to your needs. Contact Deepmould today and experience the difference!